Marquetry panels for builders Tersons Ltd

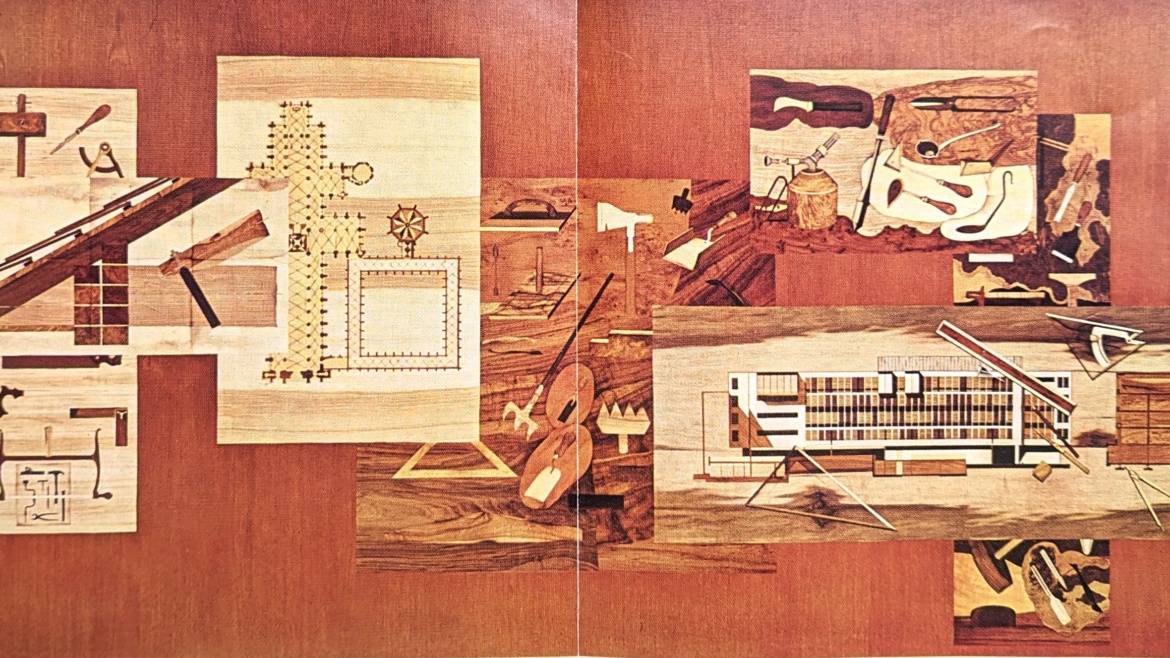

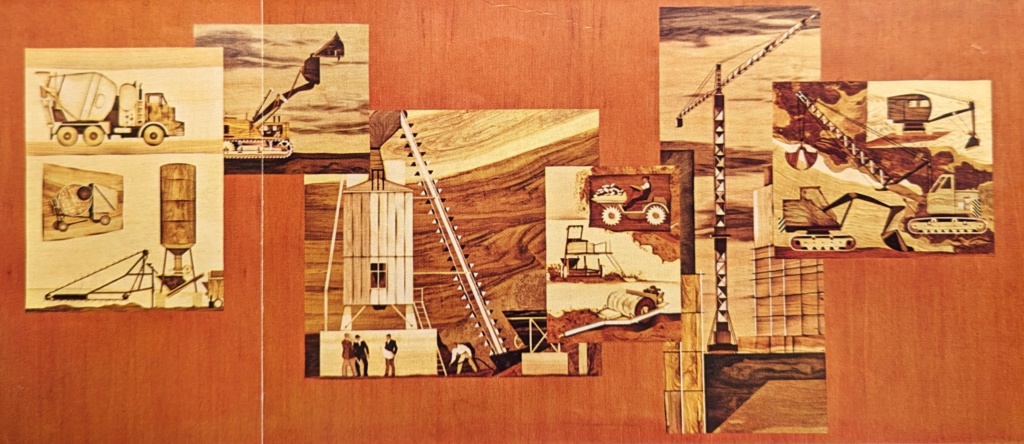

The marquetry panels for builders Tersons Ltd are for the reception hall at Winston House. In the main ground floor area, there are two large marquetry mural panels showcasing the art of the builder’s trade.

The larger marquetry mural panel showcases the manual tools of the builder and the smaller mural panel shows the more modern mechanical appliances with which they work.

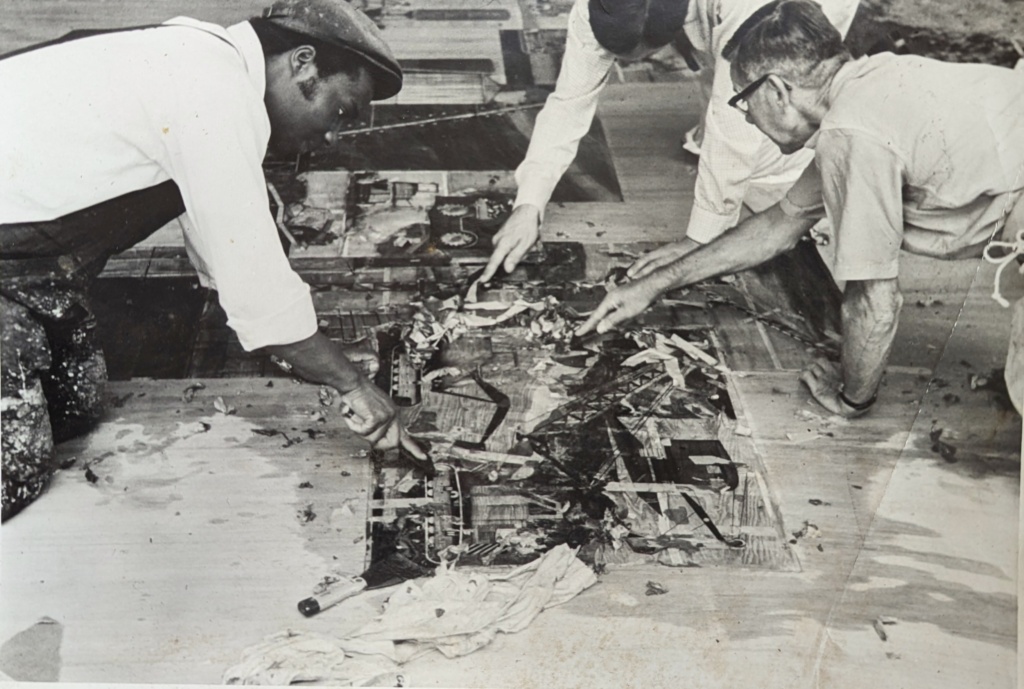

Making the marquetry.

Robert Dunn starts by making a number of photocopies from the master design drawing. One of the photocopies is to number up the pieces and to label where the different woods are going. It helps to create a picture in our mind of what the overall panel will look like, as well as helping us to know where to place each piece in the tray for drawing around.

We choose the background veneer first and the individual objects go into a contrasting veneer. When the marquetry pieces are cut and placed into the tray, they are ready for shading. Shading gives the 3D effect and it makes the Marquetry come to life.

We usually allow the pieces to ‘rest’ for 24 hours after shading. We draw around all the different pieces onto the background. When we have cut the background, the marquetry pieces are position into the background.

It is now ready for pressing.

Due to the size of the two panels, one being 23ft long, they went to a specialist firm. Care is the upmost to ensure perfect alignment before the veneer come in contact with the adhesive. The panels go into a heat press with a felt pad over the marquetry to help with any difference in veneer thickness. Once the pressing has complete, we clean the brown paper and glue off the face of the marquetry for sanding, ready for polishing.